Dematic – Counterbalance AGV Systems

Counterbalance automated guided vehicles (AGVs) — also known as Forklift AGVs — automatically pick up and deliver pallets, rolls, carts, containers, and many other transportable loads.

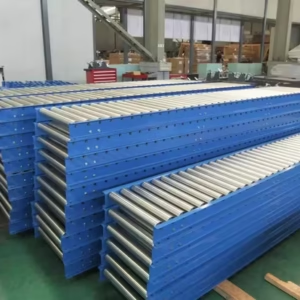

Counterbalance AGVs are the most common type of AGVs because they are so versatile. Pick up and delivery can be performed at floor level or to high bay storage stacking, deep lane, and conveyors. Counterbalance AGV systems are the ideal solution for warehouses and distribution centres but can be used for a wide range of applications:

- Moving loads from receiving to production/warehouse

- Warehousing (narrow aisle, deep-lane stacking, block storage, racking)

- Buffer storage

- End-of-line handling

- Picking from conveyors, palletizers, stretch wrappers

- Trailer loading/unloading

- Transport between production and warehouse

Counterbalance AGV Load Handling Device Types

Counterbalance AGVs come in a variety of loading devices and models:

- Standard Fork: Traditional forks as found on a manual lift truck.

- Reach Fork: The load handling device moves forward and backward to pick or drop loads to store pallets and other loads in warehouse racks. (These are also known as Narrow Aisle Reach AGVs.)

- Dual Fork: Equipped with two pairs of forks to handle two loads simultaneously.

- Single Double: Equipped with two pairs of dynamic forks that can handle a single pallet or spread the forks hydraulically to lift, carry, and side-shift multiple pallets side by side.

- Fork Positioner: Each fork independently adjusts to transport non-standard pallets.

- Carton Clamps: Uses side clamps to transport non-pallet loads.

- Top Clamp: Uses forks and a top clamp to stabilize loads during transit.

- Roll Clamps: For transporting cylindrical loads (for example, drums, paper rolls, tires).

- Push/Pull: For sliding non-pallet loads.

- Automatic Trailer Loading/Unloading (ATL/ATUL): Dematic ATL AGVs automatically load and unload semi-trailers, up to four pallets at a time.

Reviews

There are no reviews yet.